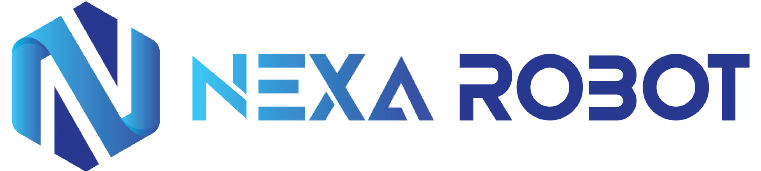

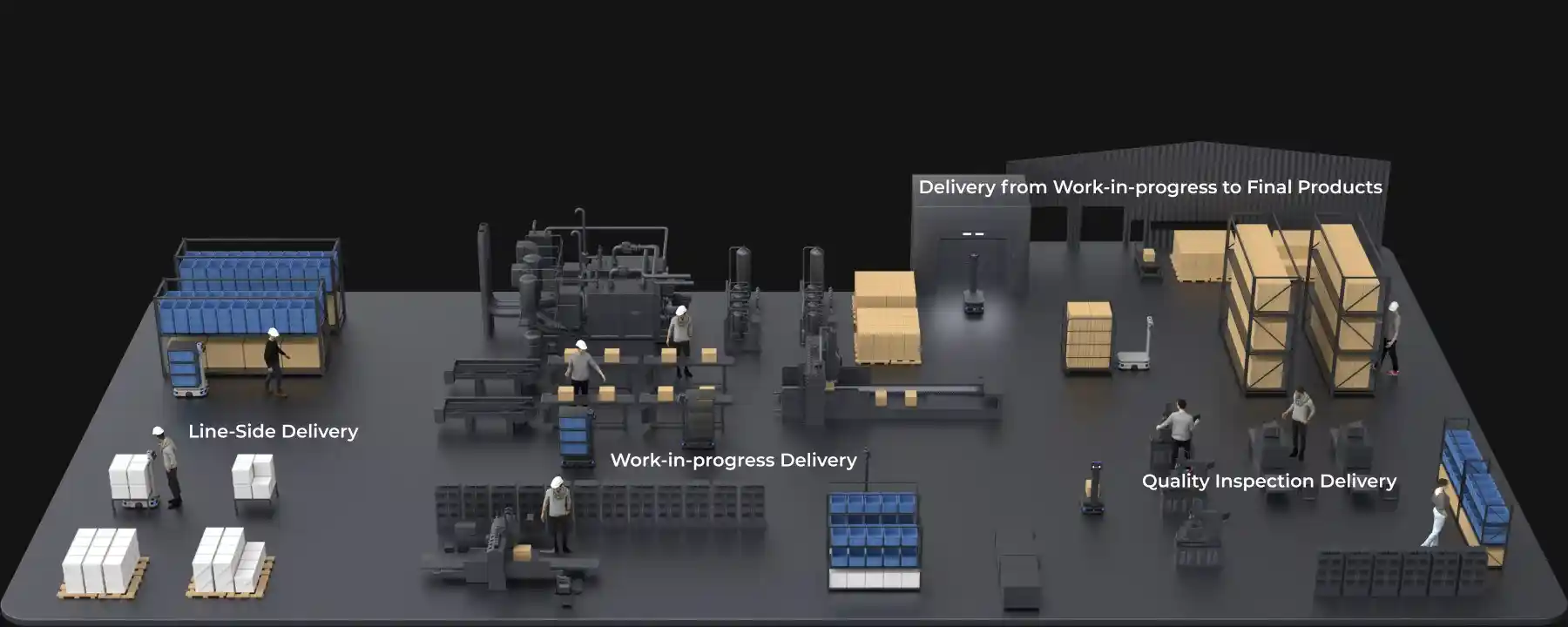

T300 Engagement in Industrial Delivery Processes

300

60

12

Vslam & Lidar SLAM

Auto & Semi-auto Delivery Modes

Auto-delivery Mode

The T300 is capable of autonomous navigation and can deliver goods to any designated destination. Additionally, you can swiftly adjust the maps to accommodate changes in the production line.

Follow Mode

The T300 employs visual recognition technology to facilitate an orderly queuing and following mechanism among multiple robots, a system primarily used for material preparation and the transportation of assorted goods.

Power-assist Mode

When manual intervention is required for specific tasks or map generation, the T300 is equipped with an electric power-assist system to facilitate hand-pushing operations, thereby enhancing delivery efficiency and convenience.

Expand Your Capabilities with Attachments

The diversified expansion of applications significantly enhances the robot’s adaptability and versatility, thereby increasing operational efficiency and simplifying procedures, ensuring a more efficient, smooth, and seamless delivery process.

Standard Mode

Shelf Mode

Lifting Mode

Towing Mode

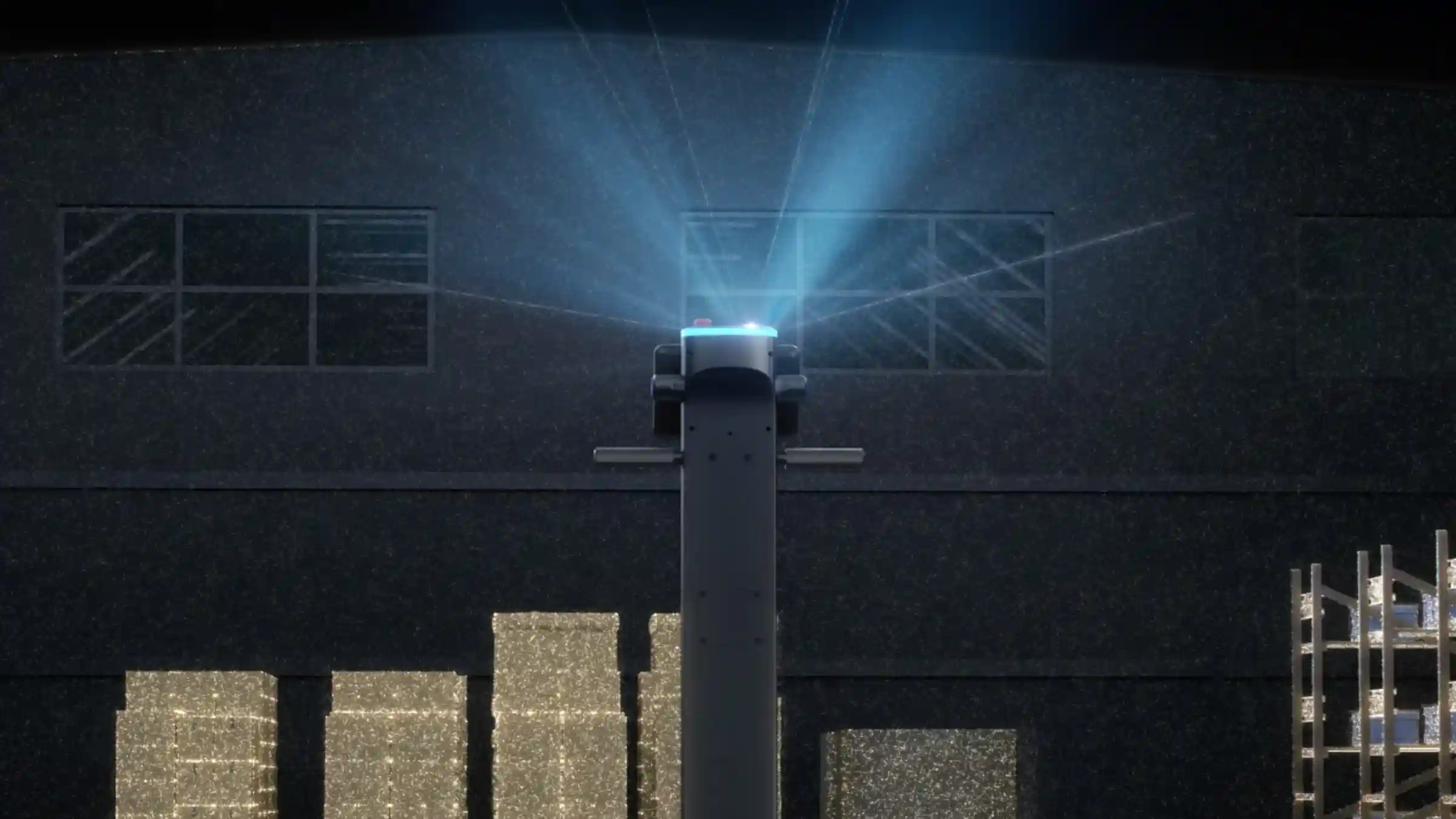

T300 VSLAM+

This allows the Nexa T300 to quickly adapt to changes in production layouts without the need for time-consuming reconfiguration or facility remodeling.

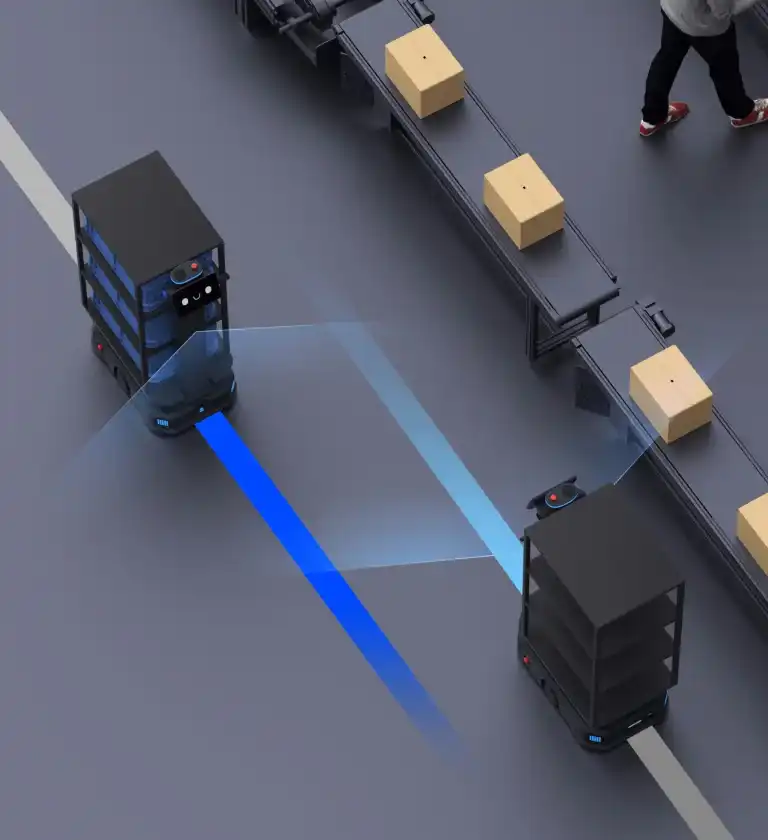

Comprehensive Safety Protection

Compliant with the ISO 3691-4 standard, the T300 is equipped with multiple safety measures, including LiDAR sensors, depth cameras, collision protection sensors, and emergency stop buttons. It can identify various low-lying or suspended obstacles and recognize yellow safety lines on the floor, meeting the safety management requirements of factories.

Boasting an exceptional 60cm path clearance

The T300 ensures agile maneuverability in narrow human-robot cohabited spaces

Effortlessly overcoming 20mm thresholds and 35mm grooves

It facilitates precise material transport between production lines and is designed to meet elevator control requirements.

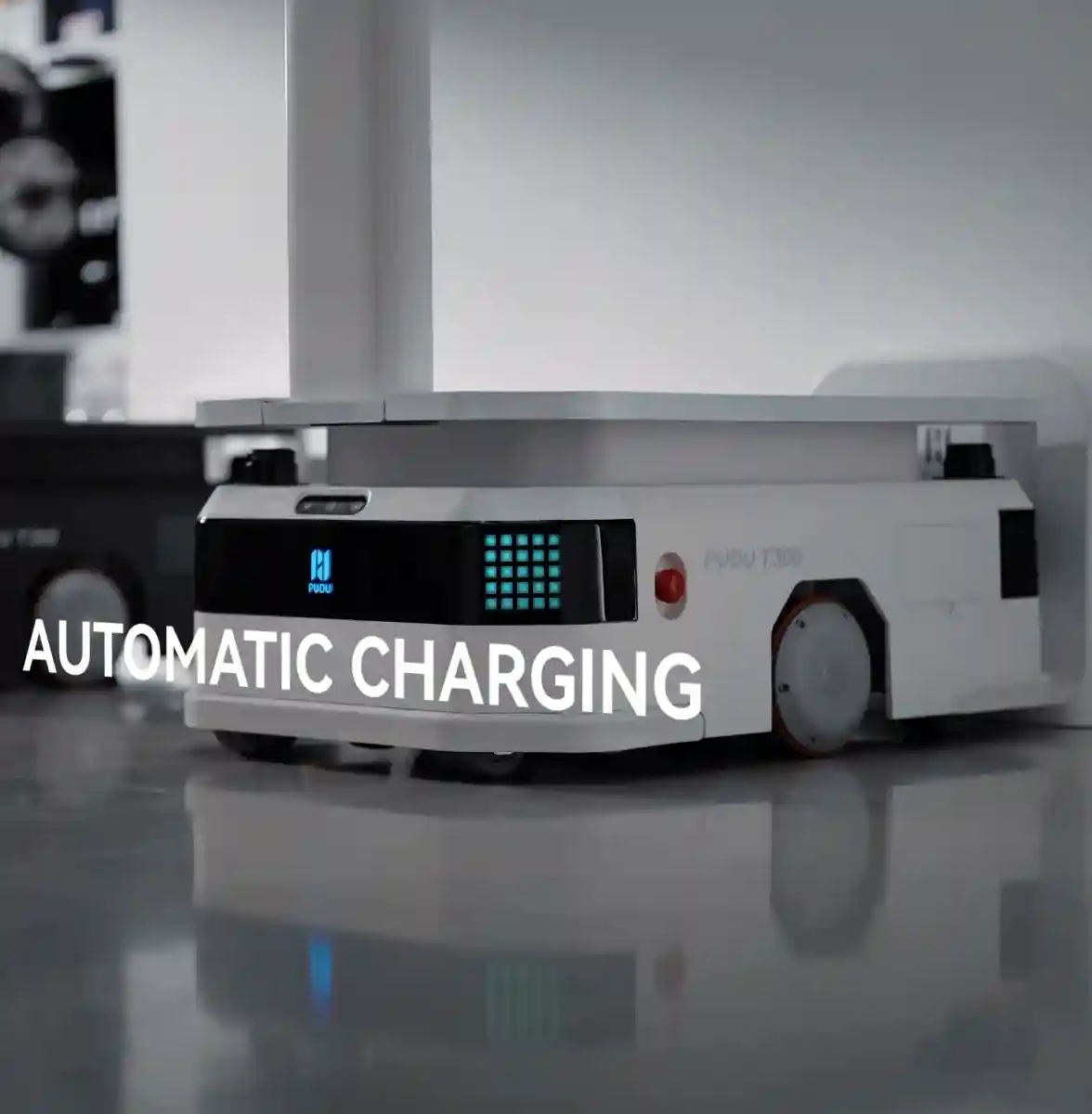

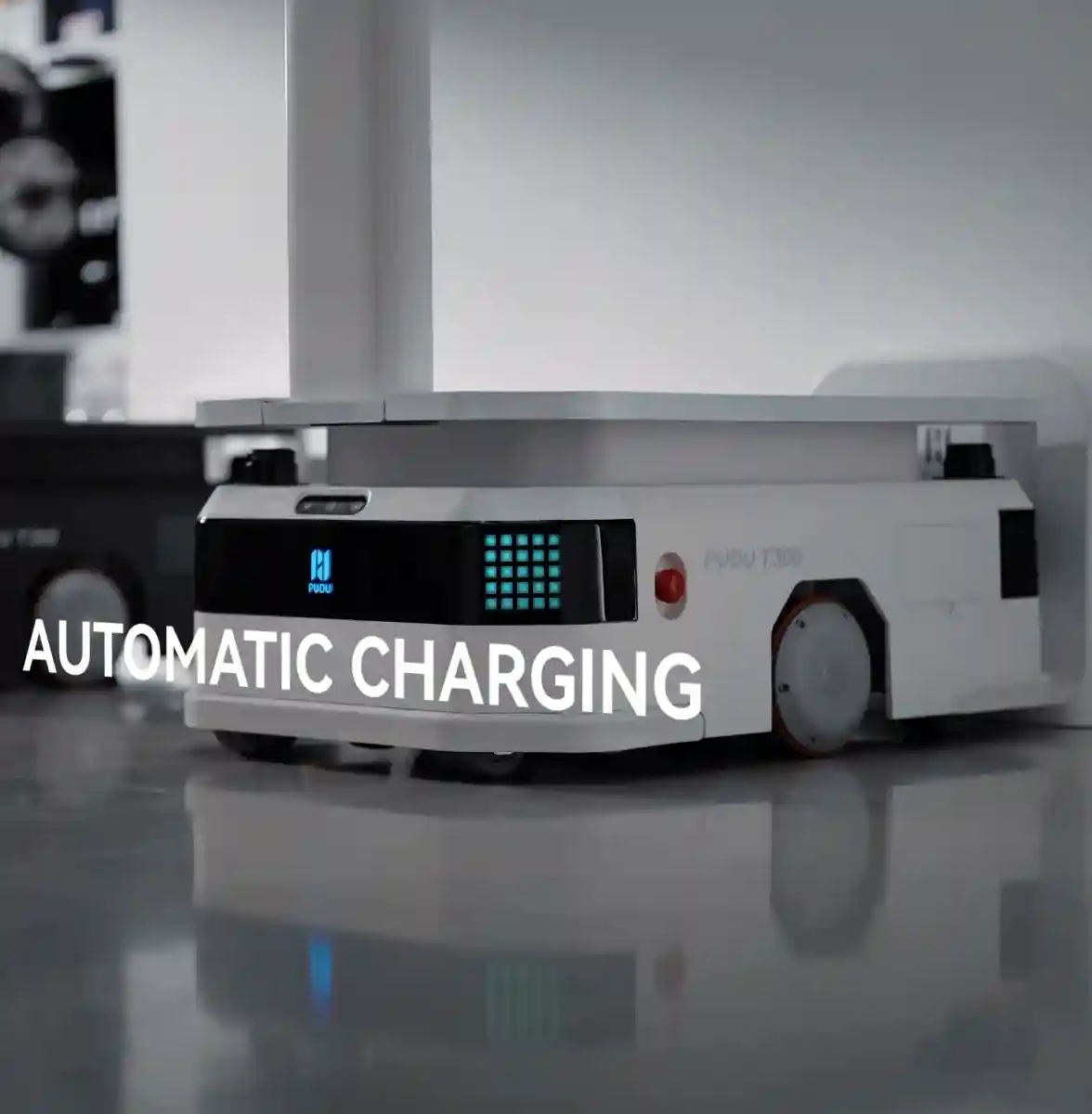

24/7 Non-stop Operations

8 hours of continuous work, 2 hours for rapid charging

The T300 offers an 8-hour battery life and supports a fast 2-hour charging capability. Equipped with both automatic recharging and battery replacement options, it ensures uninterrupted service to fulfill round-the-clock operational requirements.

Easy Changable Battery

Automatic Recharging

High-brightness operation indicator lights, clearly displaying the robot's position

Traffic signal light design visually presenting driving intentions

Customizable buttons for more organized collaboration.

Audible alerts for effective reminders.

Outstanding IoT Compatibilities, Overpass Your Expectation

There is no need to perform cumbersome system opening actions, and it can be modularly connected to the production process and applied efficiently.

Call with pager

Autonomous crossing e-gates

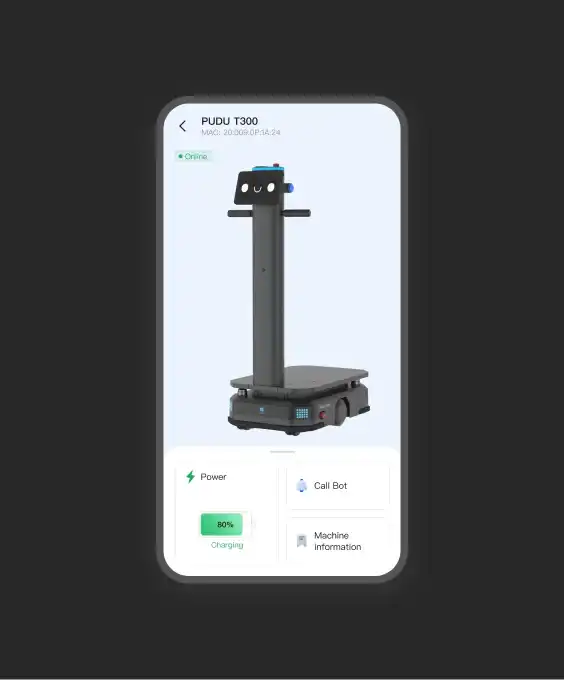

Manage with link app

Autonomous take the elevator

T300 Engagement in Industrial Delivery Processes

300

60

12

Vslam & Lidar SLAM

Auto & Semi-auto Delivery Modes

Auto-delivery Mode

The T300 is capable of autonomous navigation and can deliver goods to any designated destination. Additionally, you can swiftly adjust the maps to accommodate changes in the production line.

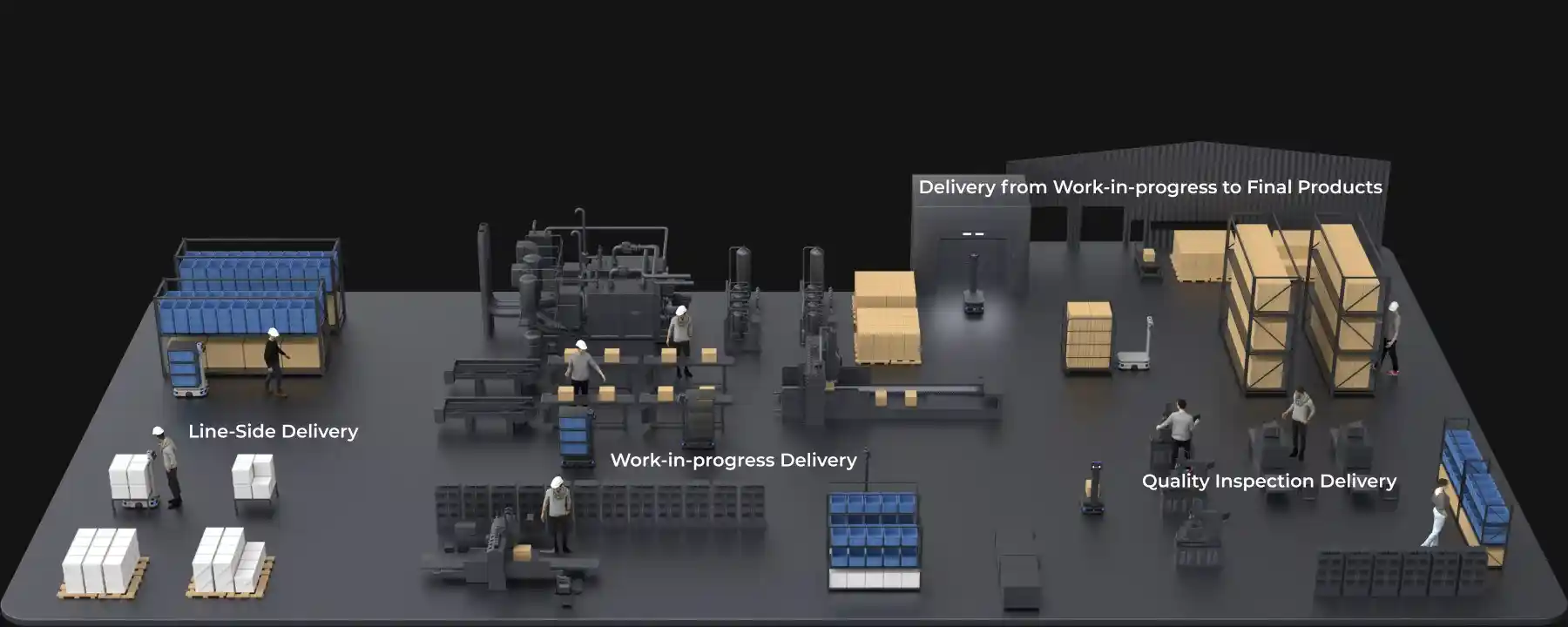

Follow Mode

The T300 employs visual recognition technology to facilitate an orderly queuing and following mechanism among multiple robots, a system primarily used for material preparation and the transportation of assorted goods.

Power-assist Mode

When manual intervention is required for specific tasks or map generation, the T300 is equipped with an electric power-assist system to facilitate hand-pushing operations, thereby enhancing delivery efficiency and convenience.

Expand Your Capabilities with Attachments

The diversified expansion of applications significantly enhances the robot's adaptability and versatility, thereby increasing operational efficiency and simplifying procedures, ensuring a more efficient, smooth, and seamless delivery process.

Standard Mode

Shelf Mode

Lifting Mode

Towing Mode

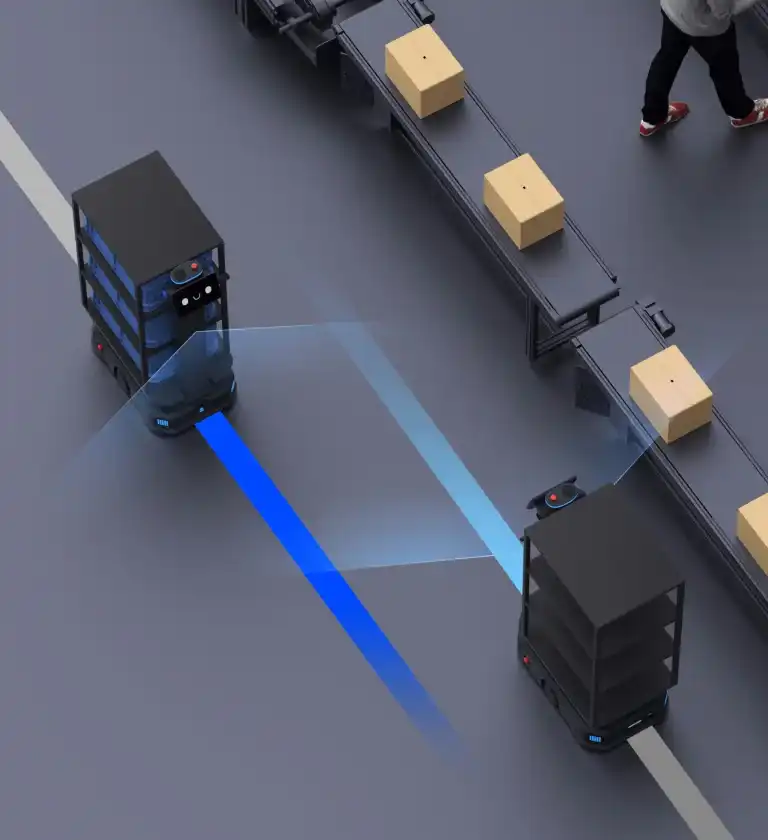

T300 VSLAM+

This allows the Nexa T300 to quickly adapt to changes in production layouts without the need for time-consuming reconfiguration or facility remodeling.

Comprehensive Safety Protection

Compliant with the ISO 3691-4 standard, the T300 is equipped with multiple safety measures, including LiDAR sensors, depth cameras, collision protection sensors, and emergency stop buttons. It can identify various low-lying or suspended obstacles and recognize yellow safety lines on the floor, meeting the safety management requirements of factories.

Boasting an exceptional 60cm path clearance

The T300 ensures agile maneuverability in narrow human-robot cohabited spaces

Effortlessly overcoming 20mm thresholds and 35mm grooves

It facilitates precise material transport between production lines and is designed to meet elevator control requirements.

24/7 Non-stop Operations

8 hours of continuous work, 2 hours for rapid charging

The T300 offers an 8-hour battery life and supports a fast 2-hour charging capability. Equipped with both automatic recharging and battery replacement options, it ensures uninterrupted service to fulfill round-the-clock operational requirements.

Easy Changable Battery

Automatic Recharging

High-brightness operation indicator lights, clearly displaying the robot's position

Traffic signal light design visually presenting driving intentions

Customizable buttons for more organized collaboration.

Audible alerts for effective reminders.

Outstanding IoT Compatibilities, Overpass Your Expectation

There is no need to perform cumbersome system opening actions, and it can be modularly connected to the production process and applied efficiently.

Call with pager

Autonomous crossing e-gates

Manage with link app

Autonomous take the elevator

Product Overview

Machine dimension

Machine Weight

Machine weight

Battery Capacity

Charging Time

Run-time

Maximum Operating Speed

Navigation Methods

Minimum Path Clearance

60 cm

Threshold Crossing Height

Groove Crossing Width

Operating Environment